Biology by design.

Biology is the most advanced manufacturing technology on the planet. We program cells to make everything from food to materials to therapeutics.

What We Do

End-to-End Capabilities. Unparalleled Scale.

Explore Ginkgo’s capabilities for therapeutics and vaccines, agriculture, nutrition and wellness, and more.

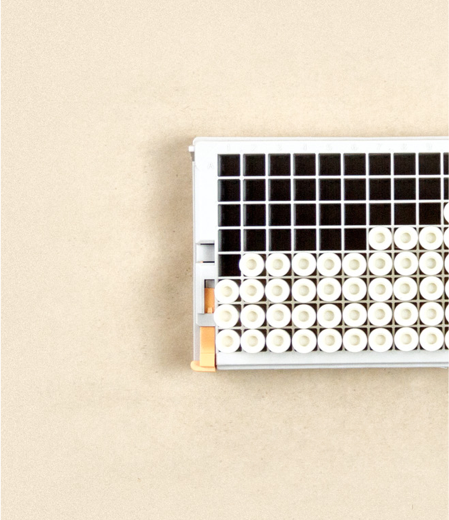

Enzyme Services

Discover, engineer, optimize, and scale up enzymes for your application

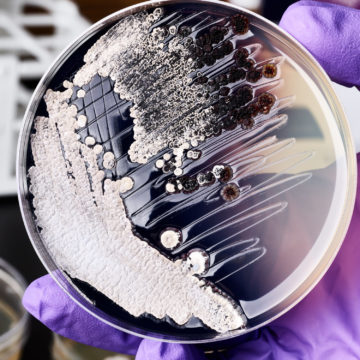

Protein Services

Discover and optimize the production of novel proteins for a variety of applications

Metabolic Engineering Services

Engineer and optimize biosynthetic pathways for small molecules

Strain Optimization Services

Screen millions of strain variants to optimize for your application

Process Design & Scale Up Services

Scale up your fermentation from 250 mL to >50,000 L on our platform

Biosecurity Services

Design a multi-layered biosecurity program to protect the things you care about the most

Our Projects

Markets We Serve

Explore how biology is being used across industries and how Ginkgo can help you.

Agriculture

Crop protection and nutrition, animal health and wellness, carbon solutions: we’re here to help

Biopharmaceutical

Use our synthetic biology platform to discover, optimize, and scale up a wide range of therapeutic modalities

Governments

Secure the things you care about the most — your people, your environment, your home

Industrials

Chemicals, materials, fuels, waste, mining, water treatment: biology is revolutionizing industrial processes

Nutrition & Wellness

Improve proteins and enzymes, fats and oils, flavors and fragrances, and so much more with synthetic biology

…and many more!

Speak with the Ginkgo team today about your industry’s needs and how biology can help solve them

Making biology

easier to engineer.

Technology