Overview

Optimizing a biocatalyst to decrease manufacturing costs

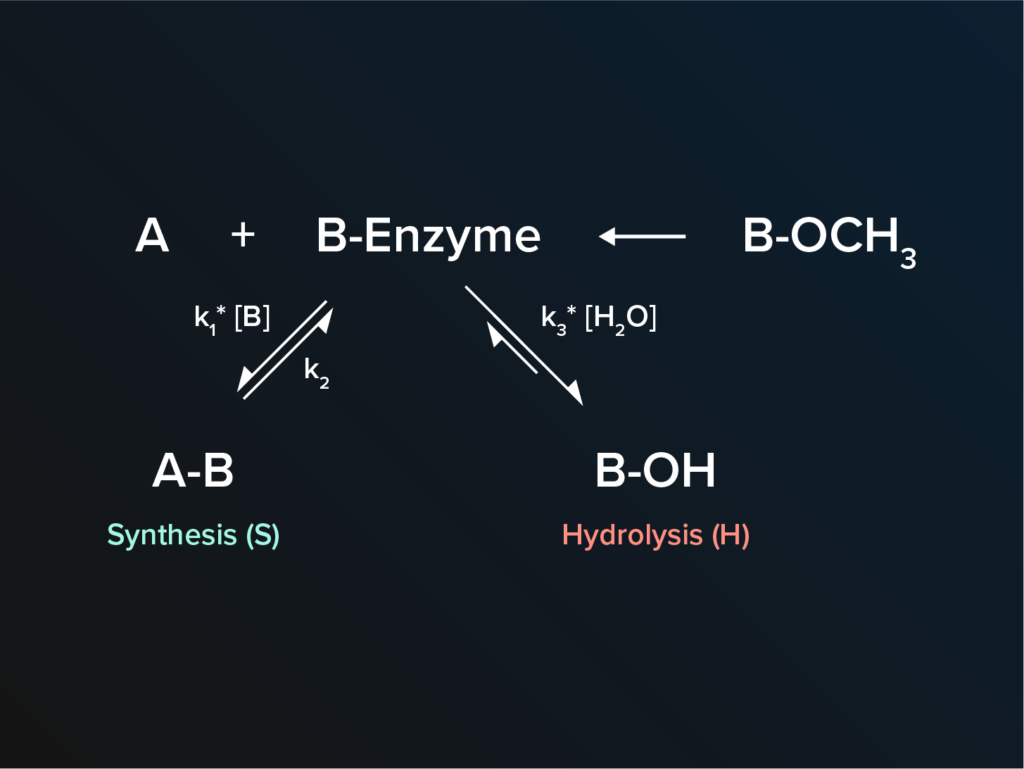

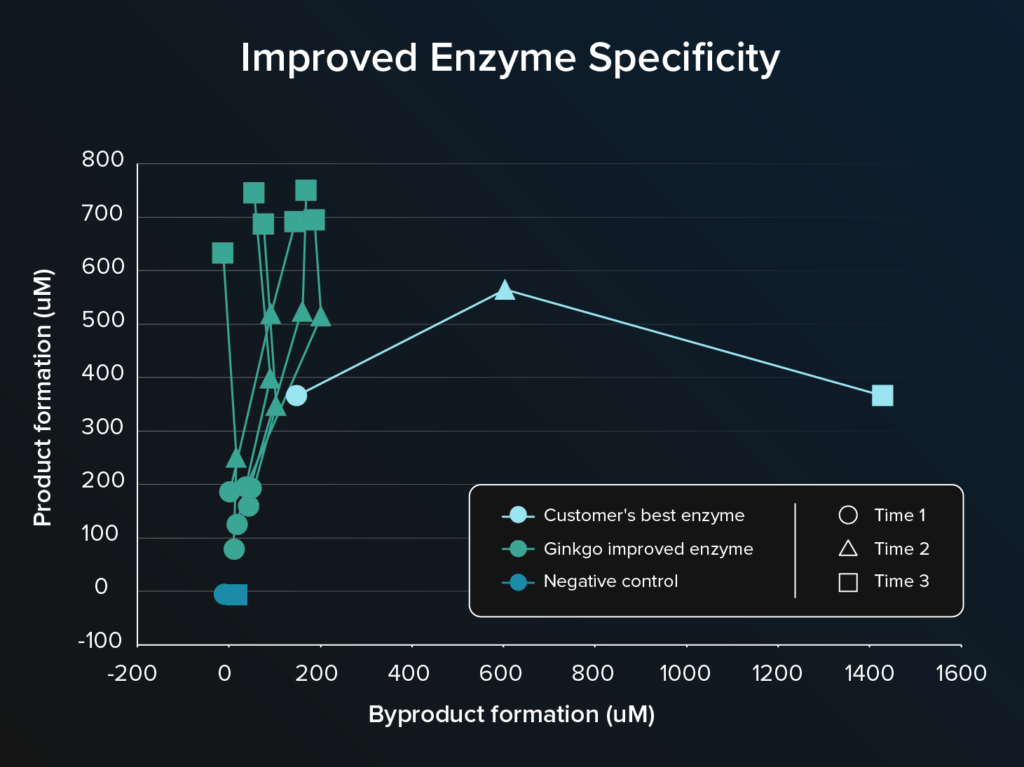

A customer’s enzyme suffered from a non-optimal synthesis to hydrolysis ratio. Working together, Ginkgo engineered enzymes to improve the activity and specificity of the biocatalyst.

In Summary

- >3.5K

- Strain tests

- 6.5x

- Improvement in biocatalyst activity

- 5x

- Improvement in desired product formation

- 1

- Design-Build-Test-Learn round to achieve these enzyme improvements

The Customer’s Requirements

Our customer wanted to reduce manufacturing costs by engineering an enzyme to improve specificity and activity. The customer’s original biocatalyst had a low synthesis to hydrolysis ratio and high formation of an undesirable byproduct.

Our Work

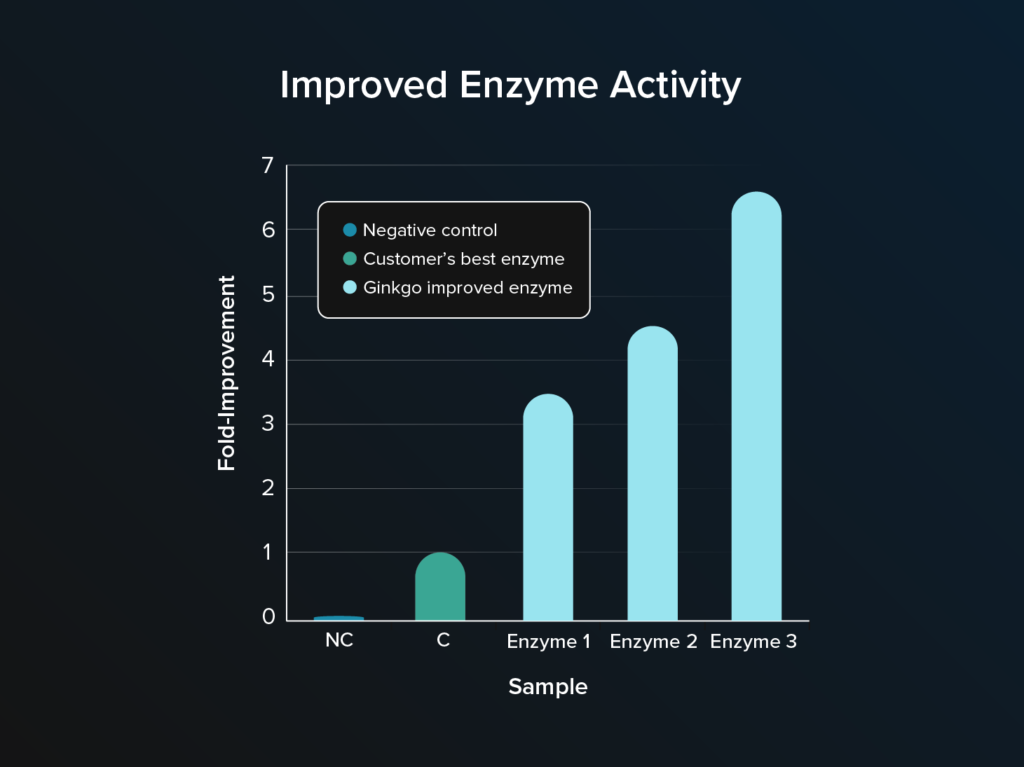

Within the first two months of initiating this project, Ginkgo designed, synthesized, and transformed a 1,100-variant enzyme library into E. coli. To design this enzyme library, we leveraged our proprietary suite of machine learning-guided protein engineering tools. These methods suggested positions in the protein where we could introduce amino acid diversity to improve the enzyme activity and specificity.

Our team carefully developed a high-throughput assay to appropriately recapitulate the real world commercial scale process conditions in order to screen these enzyme variants. This is important because this enzyme’s performance is heavily influenced by the assay conditions. To ensure the accuracy of the assay, we fine-tuned the initial concentrations of substrates, set appropriate time-points, ensured appropriate lysate dilutions, as well as other variables. We performed >3,500 strain tests across multiple time points and were able to identify enzyme variants that met our customer’s specifications.

Outcome

Within one year of starting the project and one DBTL cycle of protein engineering, Ginkgo delivered enzymes that exceeded the customer’s requirements: some variants exhibited 6.5x improvement in biocatalyst activity while others displayed 5x improvement in desired product formation.

We tech transferred the top hits from our protein engineering campaign to the customer, who has since confirmed the activity improvement at their facilities. Scale-up is in progress.