Overview

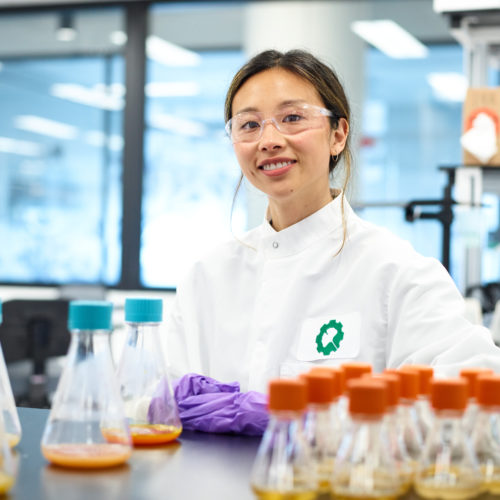

Help derisk and accelerate timeline to protein production.

Whether you’re looking to get a headstart with Ginkgo’s top-tier tailored fungal & yeast strains, optimize strain performance for protein production, hit higher titers with classical strain improvement using non-GM approaches, or increase scale up production efficiency, Ginkgo’s best-in-class capabilities empower your protein R&D.

Have a question or ready to start a project?

Overcome Protein Expression Bottlenecks.

with Ginkgo’s end-to-end capabilities.

Proteins play a pivotal role in influencing taste, texture, and health benefits. These functionalities are governed by protein sequences and cell-mediated modifications during production, which often pose challenges for precision fermentation and cell engineering. For instance, dairy proteins’ hydrophilicity is crucial for cheese function but makes it susceptible to degradation within cells.

Optimizing production hosts is essential to enable the fermentation of these proteins. This involves eliminating proteases, introducing chaperones, creating promoters, expression systems, and tailoring them to each protein’s unique requirements. The process also entails design, downstream processing, and scale-up efforts.

Successfully bringing a protein to market is a complex journey. Leverage Ginkgo’s expertise to access rapid and scalable solutions. From host selection to optimizing your host strain development and scaling, Gingko Protein Services help you overcome bottlenecks, cut capital expenditure, expedite development, and reduce R&D risk.

We’ve invested significantly in developing our in-house suite of host strains, specifically designed for glycoprotein, iron-bound, and structural protein production, with the goal of enhancing titer and functionality, including protein targets within sweeteners, alternative dairy, alternative egg, thickeners and preservatives.

How can we help you?

Host Strain Headstarts

Host Strain Headstarts

Ginkgo’s advanced strains are designed for specialized protein expression. Our dedication to this effort stems from the extensive research and pre-work invested in enhancing these suites of strain backgrounds. We’ve focused on genome modifications: multi-copy integrations, codon optimizations, secretion signals, tunable promoter systems, post-processing, and folding machinery to improve titer and functionality.

We can help you:

- Derisk host strain selection for further protein engineering by drawing from our suite of fungal and yeast strain backgrounds that are specially optimized to express functional properties of key protein ingredients, such as iron binding, as well as protein stability and secretion

- Already have a host you want to work with? We can evaluate, compare, and onboard your host strain

- Plate-scale samples from Ginkgo’s assets for testing

- Identify suitable production strain for GRAS filing & scaling

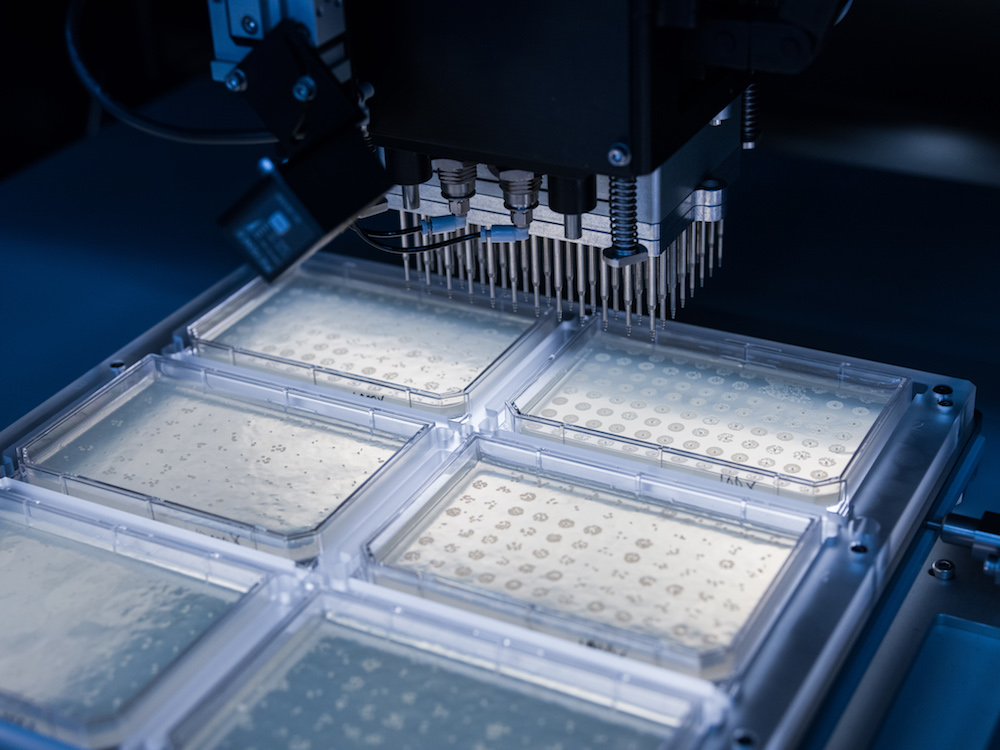

Optimize Strain Performance

Optimize Strain Performance

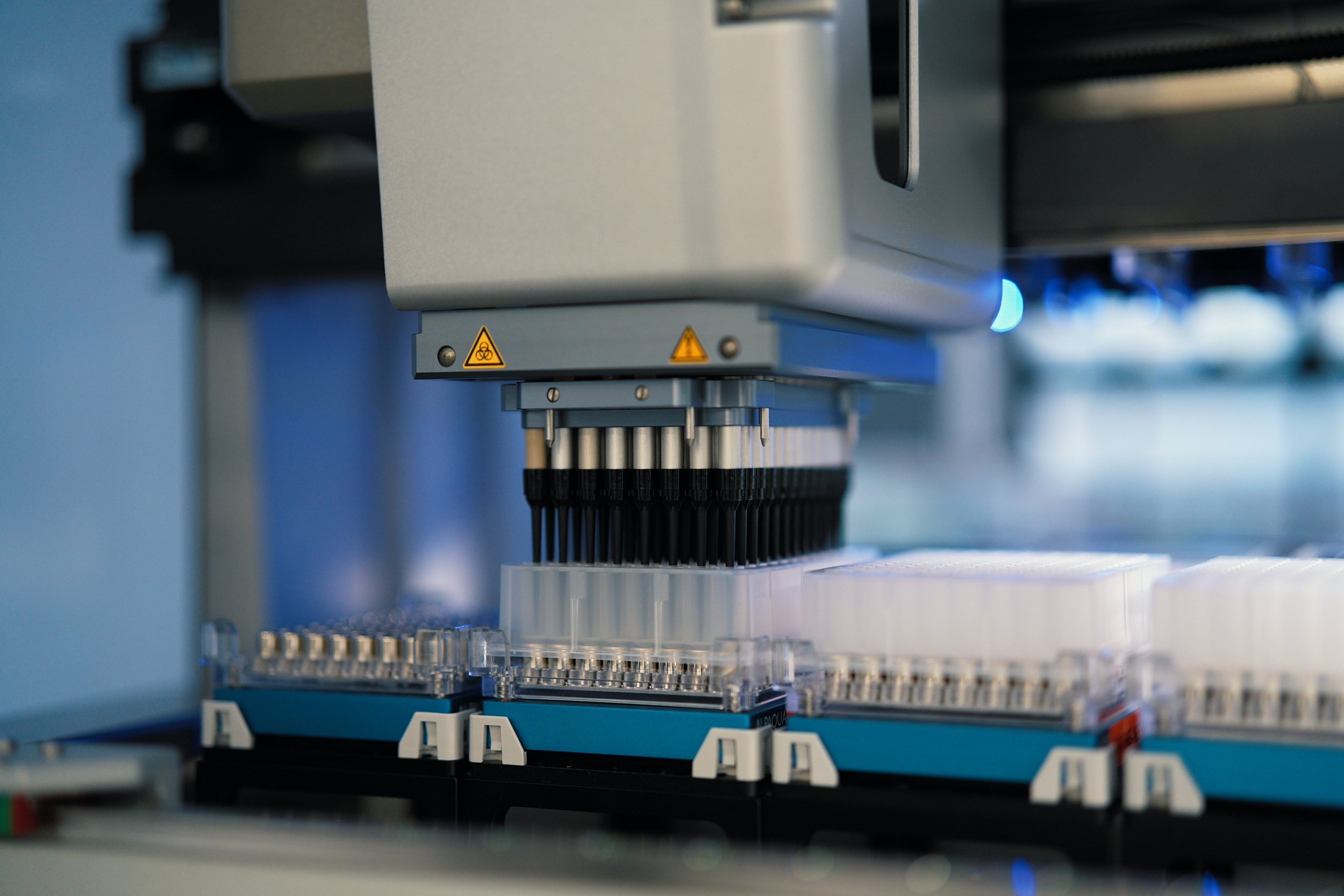

Speed up research & development with our broad and constantly expanding toolkit of genomic parts, and ultra high throughput screening approaches— to iteratively improve your host strain for improved protein functionality, stability, bioactivity, expression, and more.

We can help you:

- Optimize expression with proprietary methanol-free expression constructs in Pichia yeast and filamentous fungi

- If you have your own strain, Ginkgo applies expert analytics to your strain, including biodiagnostics like transcriptome or proteome analysis

- Accelerate development: screen tens of thousands strains per campaign using automated High-Throughput screening workflows

- Strain engineering towards easier down-stream processing, meeting regulatory specifications

- Strain engineering towards COGs improvement and functionality

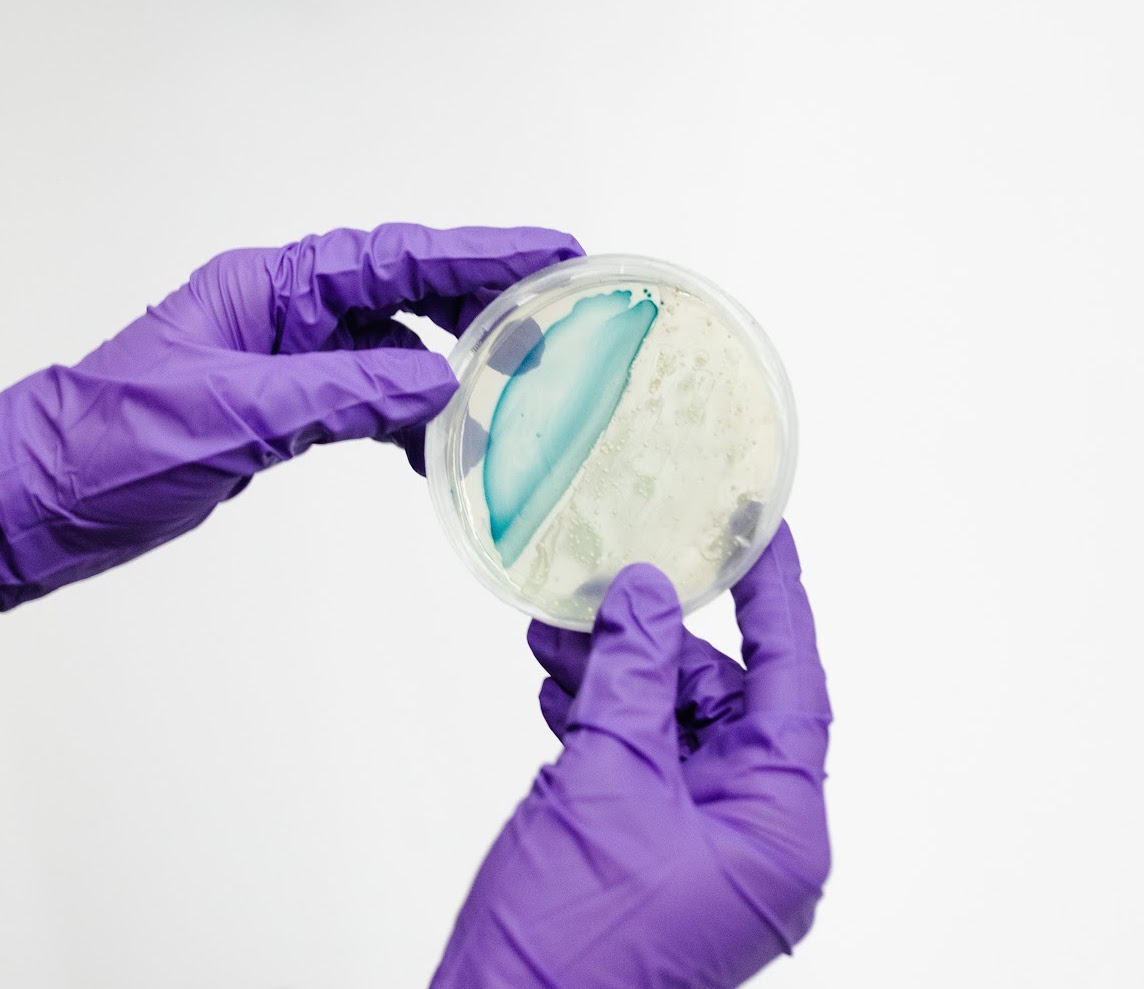

Classical Strain Improvement

Classical Strain Improvement

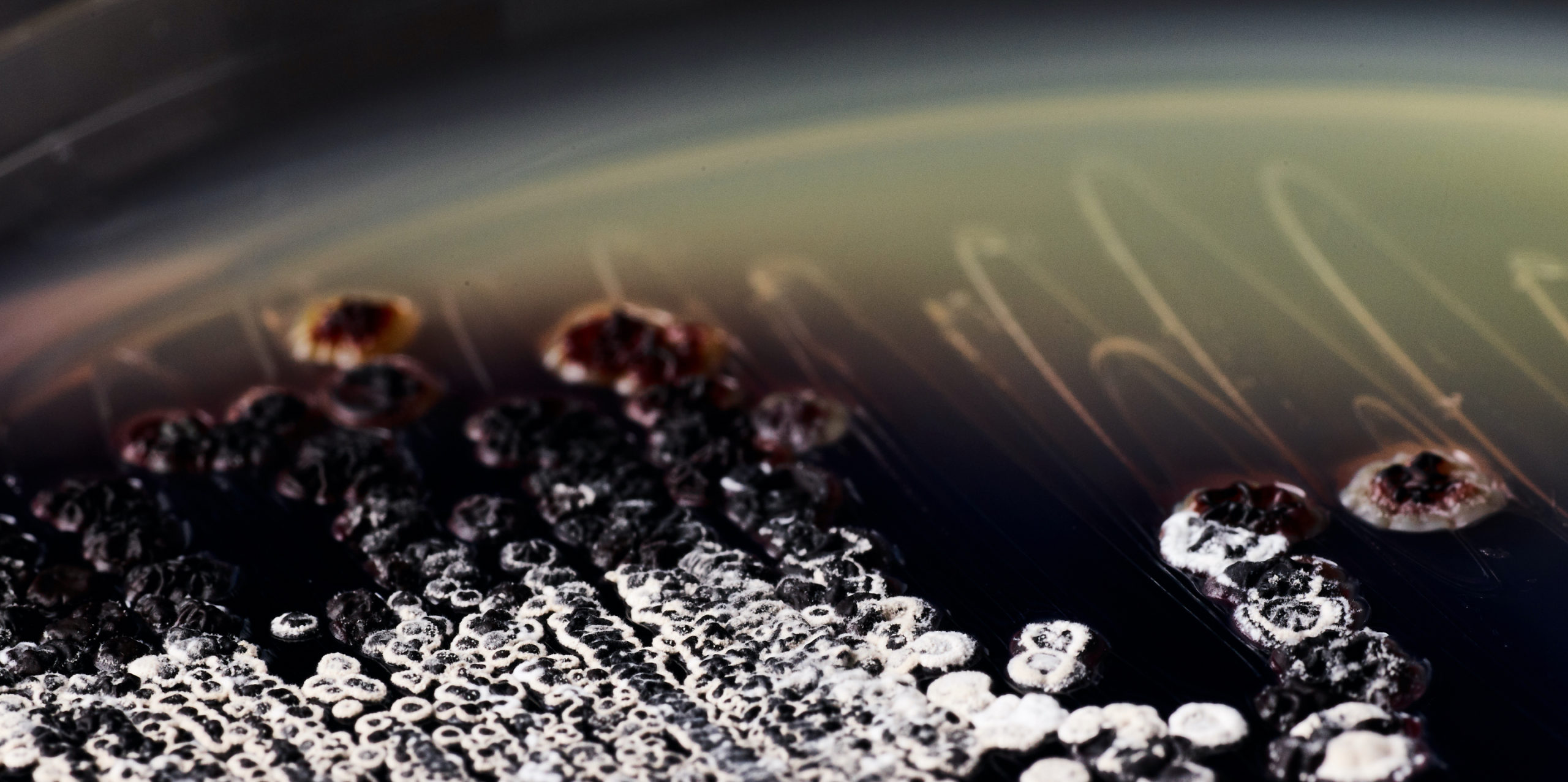

Ginkgo’s advancements in classical strain improvement (mycelium included) includes UV, chemical mutagenesis, encapsulation and screening, allowing for further improvement and step changes in protein titer.

We can help you:

- Improve production strains using non-GM approaches (mutagenesis, encapsulated screen)

- Modify protein or biomass content in your mycelium for alternative food applications

- If your have your own host strain, Ginkgo refines your strain through random engineering (such as ENCAPS, transposon based mutagenesis)

- Generate 250mL-scale samples and Omics analysis (proteomics)

- Circularize your process by switching carbon sources using Adaptive Lab Evolution ALE

Increase Scale-Up Production Efficiency

Increase Scale-Up Production Efficiency

Access our diverse fermentation capacity, ranging from Ginkgo’s fleet of ~300 Sartorius Ambr® 250 bioreactors to vessels ranging from 1 to 50,000 L with our trusted manufacturing partners, including GMP production. Optimize downstream processing to meet regulatory specifications, perform functionality testing, and utilize Ginkgo’s thermal, physical, and chemical separation capabilities for efficient purification, enabling further analysis, testing, or proof of concept.

We can help you:

- Optimize fermentation at 30L+ scale, generate samples

- Purify a sample protein for further analysis or proof of concept

- Help you outsource specific functionality testing of proteins with our CDMO partners

- Seamless technology transfer to your team or to your manufacturing partner of choice

- Downstream processing

Markets We Serve

Agriculture

Biopharmaceutical

Governments

Industrials

Nutrition & Wellness

…and many more!

Speak with Us

Start a project today.

We program cells—enabling you to grow the future of medicine, materials, food, and more.

Featured Projects & News

Speak to our team today to access more.