Overview

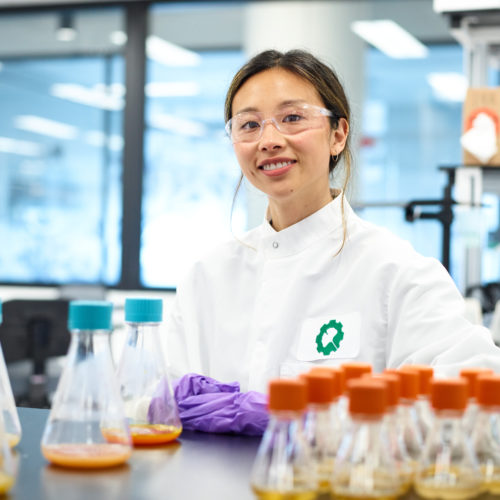

Scale up and deploy your optimized strains at commercial scale

Utilize Ginkgo’s best-in-class scale up, processing, and production services at bench, pilot, and commercial scales. Ginkgo’s capabilities enable and improve the scaled production of your product whether a cell or gene therapy, agricultural product, food protein, industrial commodity, or anything in between.

Have a question or ready to start a project?

End-to-End Capabilities.

No Matter the Scale.

From proof of concept in well plates, shake flasks and small bioreactor systems to modeling, analytical and process development, characterization, and commercial launch, Ginkgo’s services can help you move from R&D to scaled production.

Leverage Ginkgo’s internal labs and capabilities including quality control, upstream production, downstream purification, pilot plant facilities, technical transfer to a partnered Ginkgo manufacturing site or a CDMO preferred by the customer. Ginkgo’s team of experts will provide your project with process modeling, development, and optimization, analytical support including method development and validation as well as titer or purity determination, and tech transfer back to your team or to your preferred manufacturing partner.

How can we help you?

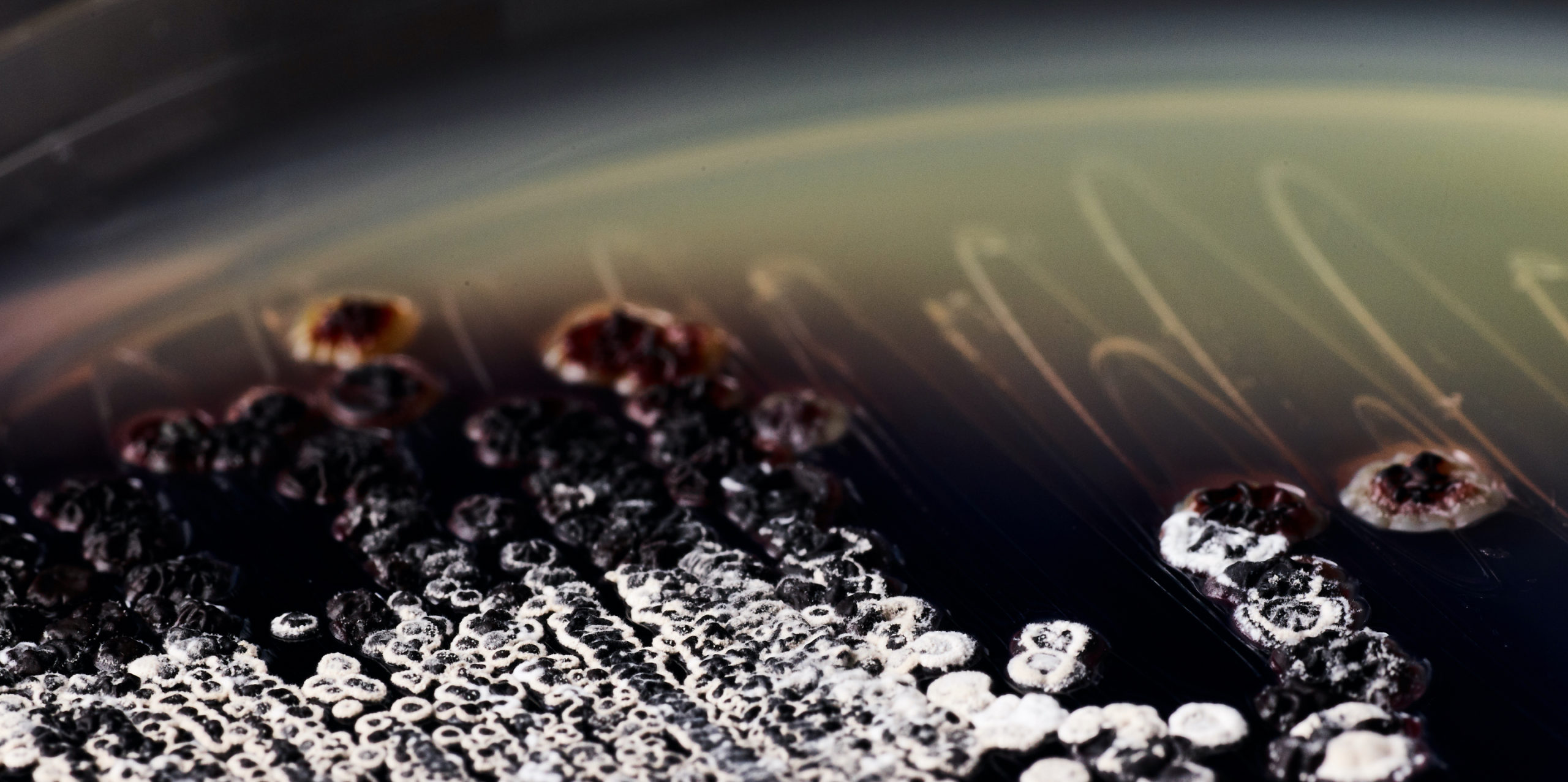

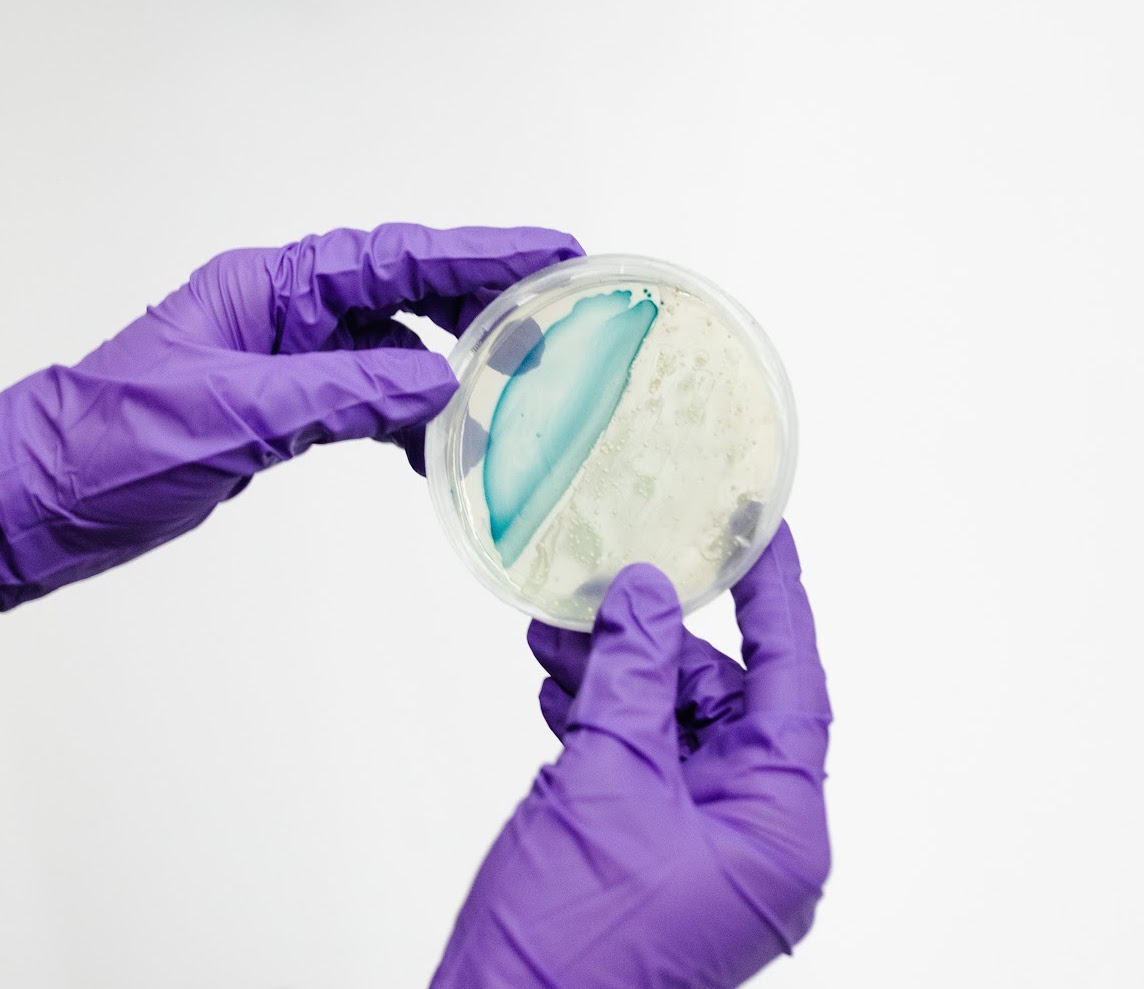

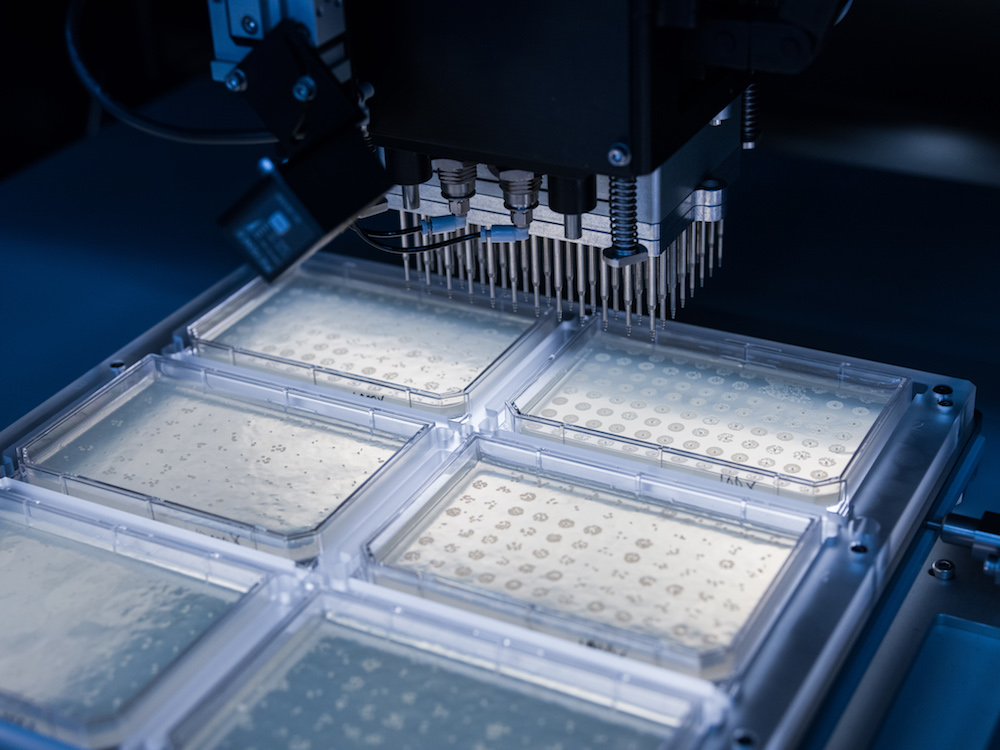

Microbial Fermentation Scale Up

Microbial Fermentation Scale Up

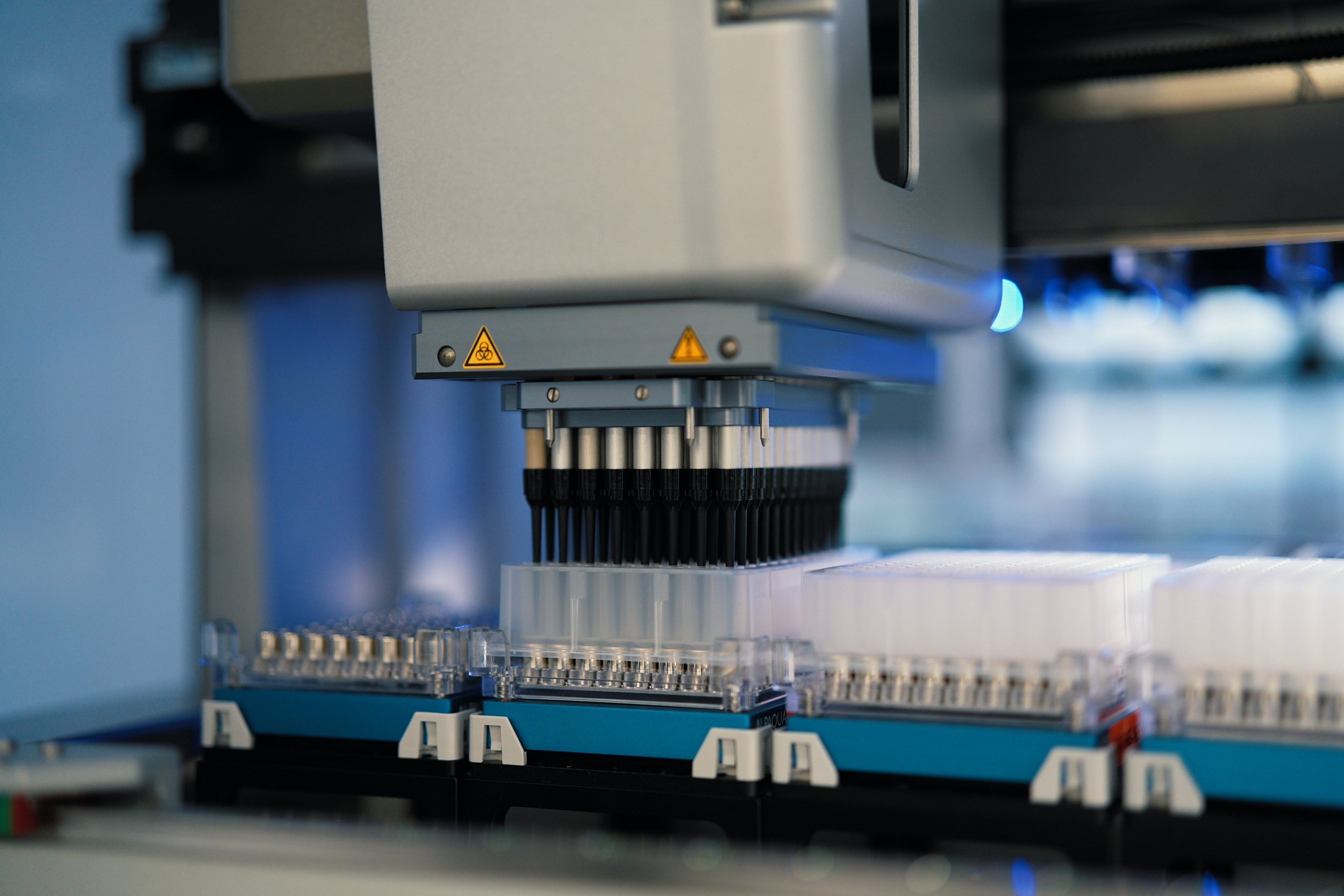

- Access our fermentation capacity, ranging from Ginkgo’s fleet of ~300 Sartorius Ambr® 250 bioreactors to our vessels spanning 1, 5, 10, 30, 300, and 3,000 L and all the way up to the 50,000 L scale with our manufacturing partners

- Rapidly evaluate strain candidates using our Ambr® 250 bioreactors to automate design of experiments at lab scale to quickly develop fermentation processes with a proven record of transferring to commercial scale

- Leverage our process optimization expertise in a range of industrial microbes—including Escherichia coli, Bacillus subtilis, Pichia pastoris, Saccharomyces cerevisiae, Aspergillus niger, Corynebacterium glutamicum, and Yarrowia lipolytica—and many more model and nonmodel host organisms

Downstream Processing

Downstream Processing

- Utilize Ginkgo’s thermal, physical, and chemical separation capabilities to purify a sample for further analysis, testing, or proof of concept

- Utilize our thermal separation capabilities including evaporation, distillation, and drying techniques

- Use our physical separation capabilities including centrifugation and filtration techniques

- Apply our variety of chemical separation capabilities including extraction, ion exchange, crystallization, chromatography, absorption, and adsorption techniques

Quality Control

Quality Control

- Receive accurate and reproducible results as an outcome of working with Ginkgo and our QC team

- Receive analytical quality support and project scoping at the start and throughout your project from our team of QC expertsLeverage our fermentation and downstream analytical titer or purity determination capabilities to accurately assess your strain’s performance

- Enjoy quick project starts thanks to Ginkgo’s incoming analytical technology transfer capabilities and ensure smooth tech transfers back to your team or to your manufacturing partner of choice

- Utilize our analytical support services to assess the capabilities of other service providers such as contract development and manufacturing organizations (CDMOs)

Pilot Plant Scale Production

Pilot Plant Scale Production

- Access the pilot scale you need by utilizing Ginkgo’s biologics pilot plant with microbial fermentation capabilities at 20, 300, and 3,000 L scales

- Process your sample using our centrifugation, tangential flow filtration, spray drying, and other purification techniques

Project Engineering

Project Engineering

- Receive cost modeling and feasibility assessments from our team to inform your decision-making

- Enjoy the benefits of Ginkgo’s project engineers who handle all aspects of contracts, procurement, scheduling, testing material, tech transfer to CDMOs and more

Markets We Serve

Agriculture

Biopharmaceutical

Governments

Industrials

Nutrition & Wellness

…and many more!

Speak with Us

Start a project today.

We program cells—enabling you to grow the future of medicine, materials, food, and more.

Featured Projects & News

Speak to our team today to access more.

Agriculture

Biopharmaceutical

Governments

Industrials

Nutrition & Wellness

Frequently Asked Questions

Not seeing what you need? Contact us with your question, and we’ll get back to you.

Contact UsIs Ginkgo able to model the cost of goods sold (COGS) and techno-economic analyses (TEA) for my project?

Yes, typically as part of early program assessment, Ginkgo’s Deployment team uses platforms such as ASPEN, SuperPro, and spreadsheets to understand the marketability and cost of commercial programs.

What scales has Ginkgo helped customer projects achieve?

We have successfully guided customer projects from our labs to commercial production at the 50,000 L scale. Internally, Ginkgo can leverage bench scale devices (250 mL to 5 L) and pilot plant equipment (10 to 3,000 L) for upstream production and downstream purification. Additionally, Ginkgo has a large network of preferred manufacturing partners who have successfully scaled our customer’s strains to commercial scale.

What are Ginkgo’s end-to-end USP, DSP, process design, and scale up services?

From proof of concept projects to tech transfers to and from customers to scale up with manufacturing partners, Ginkgo supports customers in any phase of discovery, development, optimization, and commercialization.

Does Ginkgo offer analytical development services?

Yes, Ginkgo’s QA/QC team offers analytical development. Working with process development engineers, the QA/QC team provides the best paths toward process optimization that are in alignment with the customer’s target product profile.

What services specifically does Ginkgo offer in terms of quality assurance and control?

Ginkgo’s team provides project scope assessment, analytical technology transfer, analytical method development and validation, analytical titer/purity determination, and analytical quality support internally and externally to support scaled programs.