Overview

Made by fermentation, not animal agriculture.

Motif FoodWorks — founded in 2018 and powered by Ginkgo’s platform — is discovering and developing new meat, dairy, and plant-based proteins.

The cattle industry

$1T

Global market opportunity

14.5%

Contribution to global greenhouse gas emissions

Feeding the World

To feed a rapidly growing population on a warming planet, society needs to develop innovative new technologies to grow and distribute food. The cattle industry, which includes both beef and dairy products, represents a $1 trillion global market opportunity and contributes to 9% of global greenhouse gas emissions. At Ginkgo, we are working towards a future where genetic engineering can help make foods that are sustainable, healthier, delicious, and accessible to everyone.

Discovering Proteins

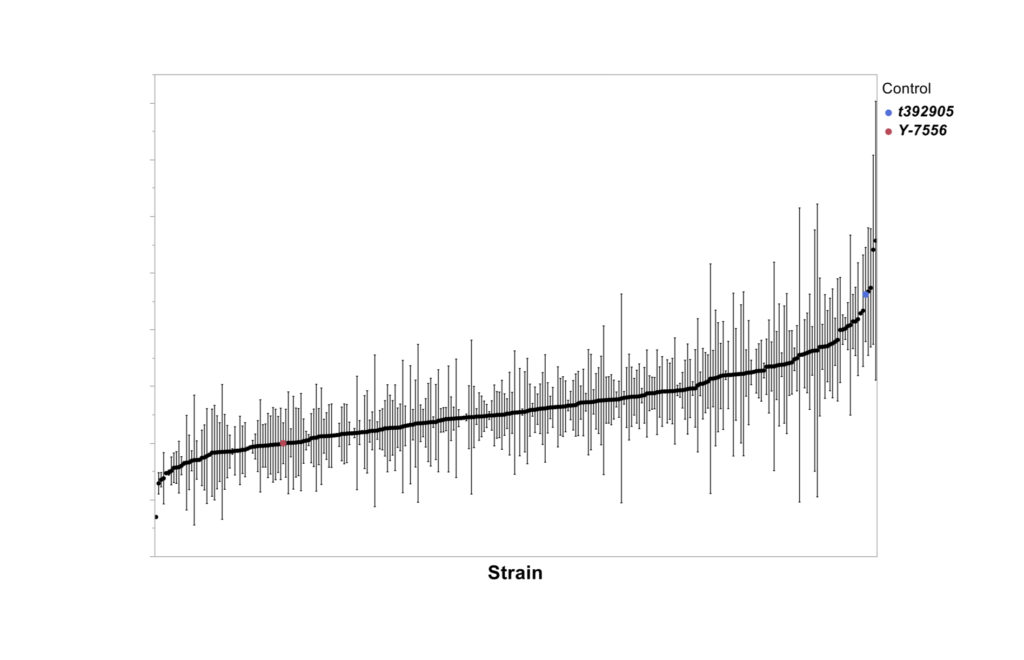

Our partnership with Motif centers on developing commercial yeast strains and processes for protein production at kilogram scale. Leveraging our Codebase and Foundry, Ginkgo’s engineers screened 300+ proteins in order to identify candidates with the greatest benefit. Following the screening process, top performers were engineered with novel expression systems to maximize protein expression.

Shortening Time-to-market

In just a year, Ginkgo developed 6 prototype strains and produced product samples for benchmarking and early application testing. We then designed, built, and validated improved variants over the next 9 months. Within 2 years, Ginkgo developed commercial strains from scratch and developed fermentation and downstream purification processes that are now being used at kilogram-scale, with a projected 3 years time-to-market for the final product. The strain’s performance exceeded Motif’s specifications by >70%. We also identified a set of novel protein expression systems that exceed performance of best-in-class systems by 5-20 fold, thereby increasing productivity, reducing cost, and improving scalability over additional rounds of engineering.

Ginkgo’s foundry can be easily repurposed to create additional food products, thereby shortening the time-to-market for each new product. We are always learning from the creativity of biology and the full breadth of biodiversity to enable the production of better, more sustainable products. For more information, visit madewithmotif.com.

In Summary

- 300+

- Proteins screened

- 6

Prototype strains developed in 1 year- 3 yr

- Projected time-to-market for the final product

- 70%

- Increase in strain’s performance over Motif’s specifications