Overview

Foundry-scale capabilities for the new wave of biologics

Ginkgo is your R&D partner for complex biologics. We offer end-to-end capabilities to bring your therapeutic from discovery, to characterization for developability, to cell-line optimization for manufacturing. As a platform synthetic biology company, we specialize in advancing our partners’ projects rather than seeking to develop our own products in-house.

The Ginkgo foundry brings together automation infrastructure, data resources and human expertise to execute biologics R&D rapidly and with the advantages of scale. We offer unique capabilities in AI-guided protein engineering and high-throughput screening, including proprietary technologies not available anywhere else.

Example biologics formats enabled by Ginkgo’s foundry services

Solutions for

- Specificity

- Epitope engineering

- Aggregation

- Degradation

- Immunogenicity

- Functional assessment

- Titer

- Manufacturability

- Cell line optimization

01 BIOLOGICS DISCOVERY

Unique screening capabilities for antibodies and other binders in ultra-high throughput

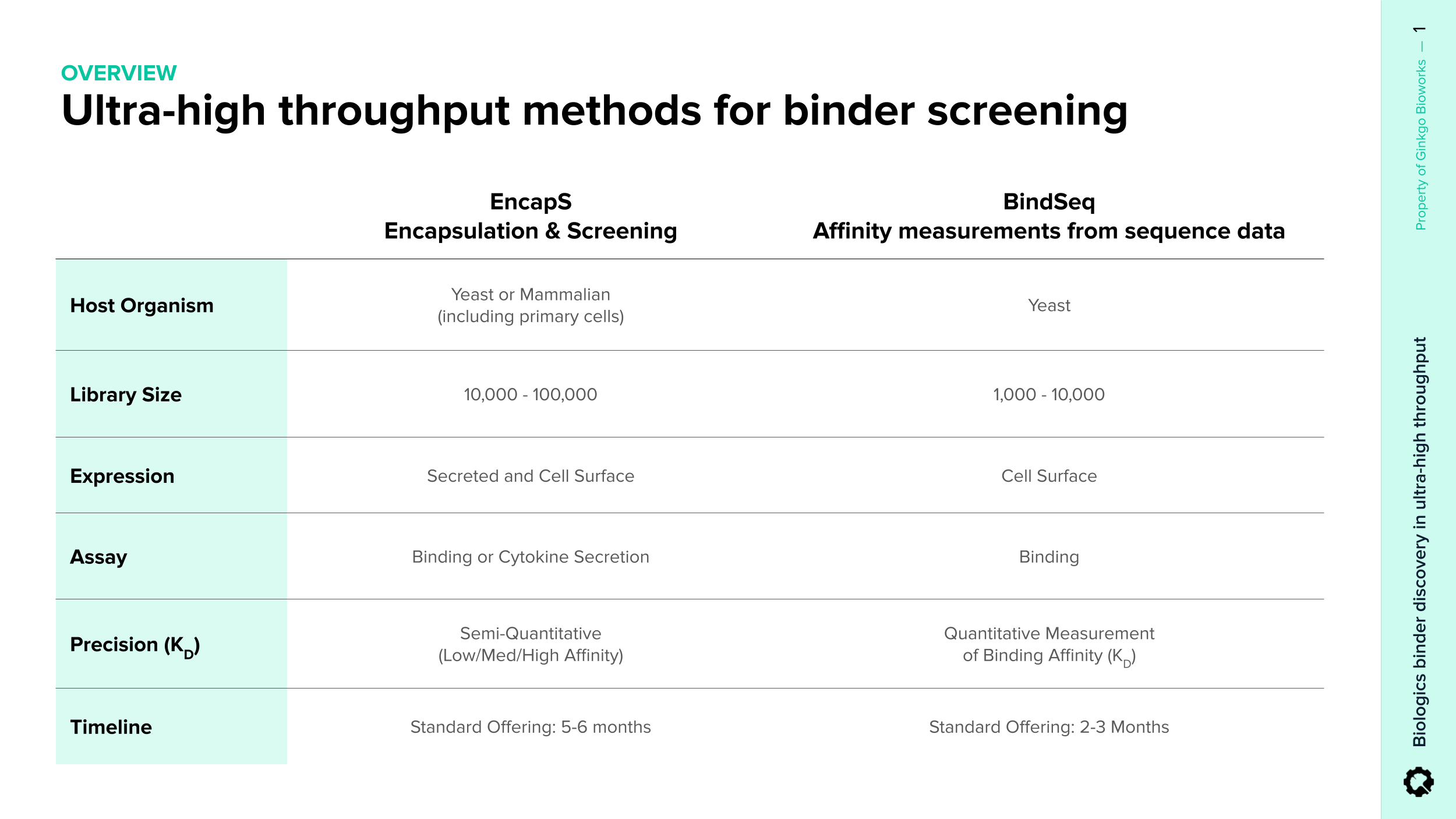

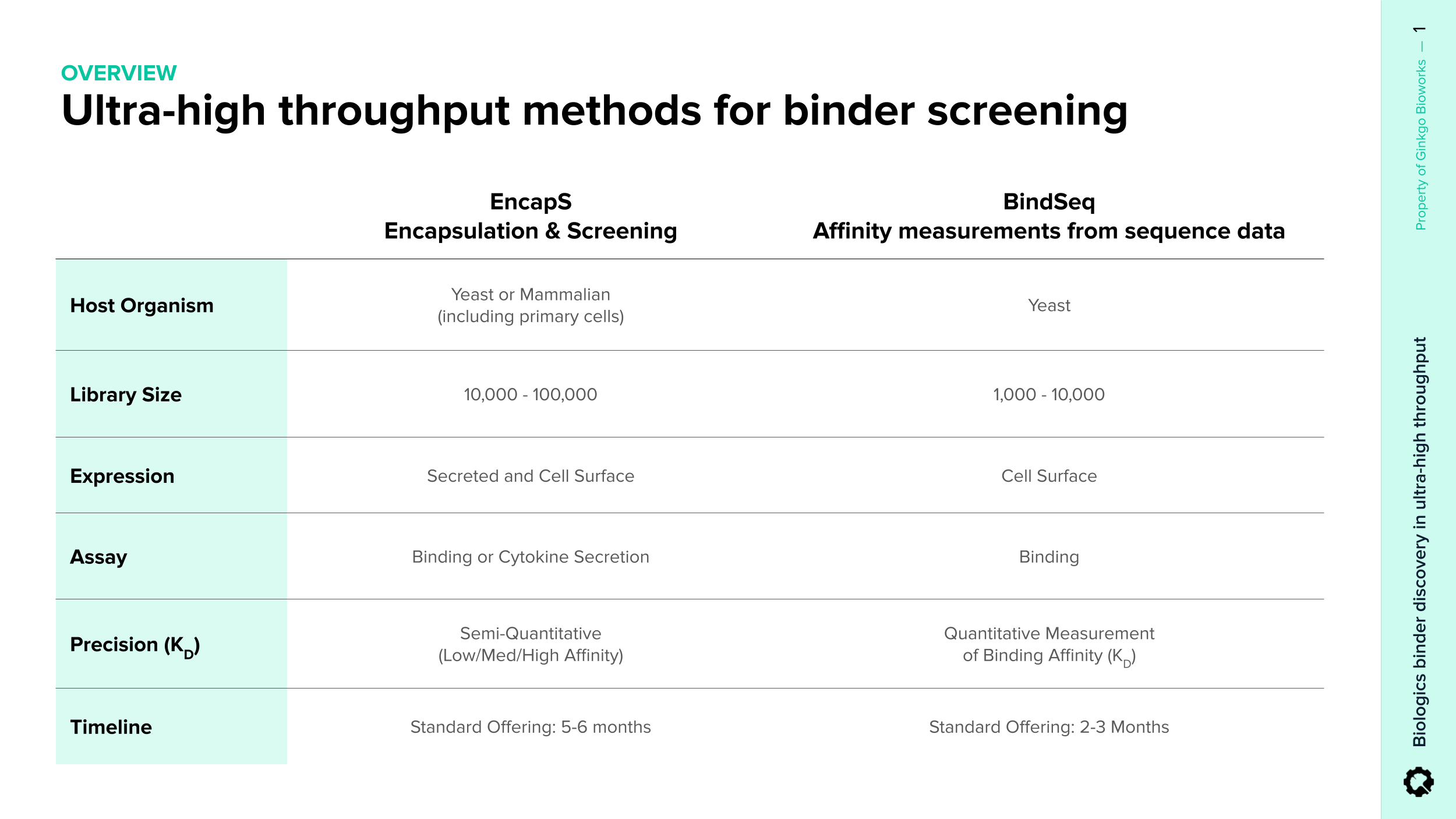

Binder discovery is often a numbers game – the more candidates you characterize, the more likely you are to find a binder with the desired affinity and specificity. R&D projects in our foundry can draw on two powerful methods for binder discovery.

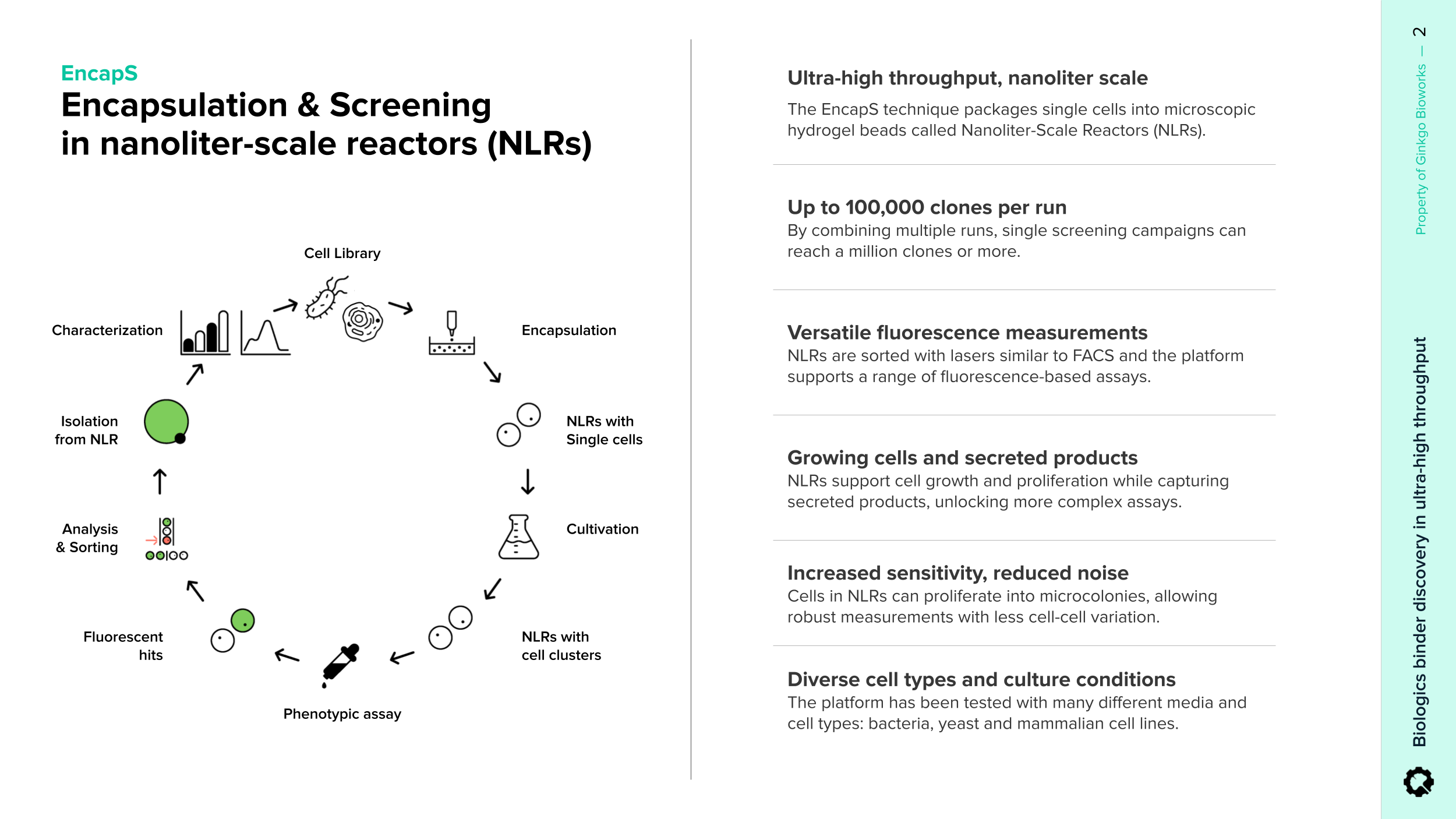

The EncapS (Encapsulation & Screening) platform captures cells in miniature hydrogel beads. These nanoliter-scale reactors allow fluorescence-based screening, similar to flow cytometry, but with the additional advantages of supporting cell growth or protein secretion over time. With EncapS, we can perform phenotypic screens for binder activity at the scale of 100,000 data points per run.

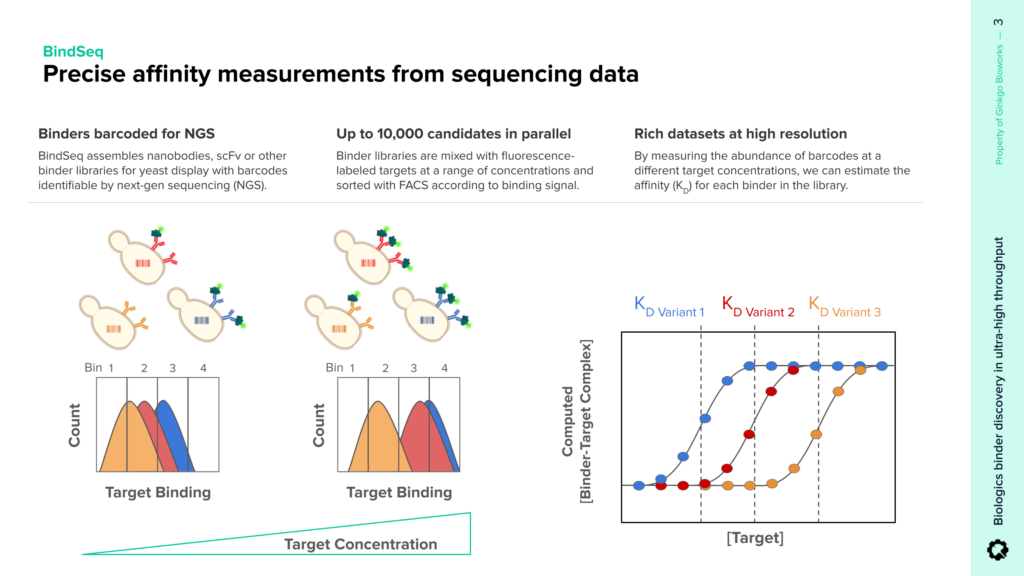

With BindSeq, we can quantitatively determine binding affinity for each of up to 10,000 candidate binders at a time. We design large libraries for yeast surface display, DNA-barcoded to enable quantification with next-gen sequencing. By serially titrating the protein library against a target, we measure the apparent affinity (KD) for each library member.

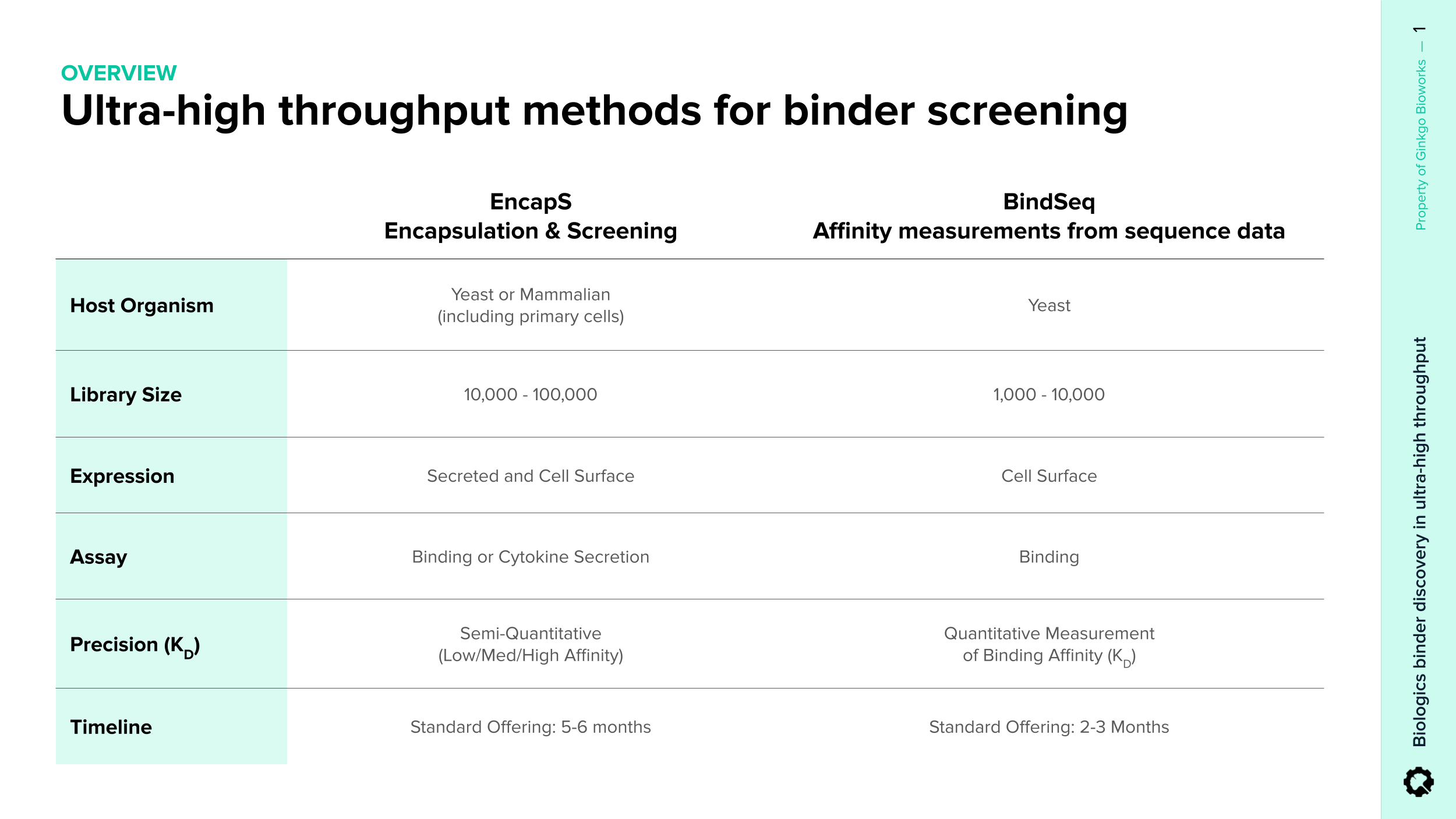

EncapS and BindSeq for antibody and binder discovery

Overview of ultra-high throughput methods for screening binder libraries

Overview of ultra-high throughput methods for screening binder libraries

EncapS and BindSeq are powerful platform technologies that can enable biologics discovery by screening binder libraries.

DOWNLOAD (PDF)EncapS – Encapsulation & Screening in nanoliter-scale reactors (NLRs)

EncapS – Encapsulation & Screening in nanoliter-scale reactors (NLRs)

EncapS allows rapid fluorescence-based screening with assays that can capture secreted products, cell growth or cell-cell interactions.

DOWNLOAD (PDF)BindSeq – Precise affinity measurements from sequencing data

BindSeq – Precise affinity measurements from sequencing data

BindSeq uses large protein libraries for yeast surface display, DNA-barcoded to enable quantitative binding measurements with next-gen sequencing (NGS).

DOWNLOAD (PDF)

Example applications of binder discovery with EncapS or BindSeq

- Complex or modified proteins not accessible by phage display or other methods

- Natural antibody repertoires such as primary B-cells

- Complex assay formats involving bi-specific antibodies

- Large scale phenotypic assays for agonist discovery

- Screening under realistic in situ conditions of manufacture or use

- Assays that require a time interval of culture in a nanoliter-scale microenvironment

- Large, quantitative and assay-labeled datasets for training generative AI

02 BIOLOGICS ENGINEERING

AI-guided protein engineering backed with large datasets and data-generating capacity

Protein design is at the leading edge of applied AI in biotech. As software tools for generative AI become widely adopted, data for training AI models is often the limiting resource. Ginkgo offers extensive in-house datasets and data-generating capabilities that support AI-guided engineering for antibodies, protein binders, enzymes, and other biologics.

Ginkgo’s software platform for AI-guided design is Owl, so-named because it can see in the dark. Owl is differentiated by the breadth of the computational tools that it integrates: sequence-based, structure-based, or assay-labeled models that learn from performance data generated here in the foundry.

Our protein engineering team has delivered engineered enzymes, antibodies and binders across dozens of projects. We’ve got the deep experience needed to take on the hardest problems in biotech.

Data resources

~2 billion protein sequences in our proprietary DNA database.

> 5 million protein designs built and tested in our foundry.

Data-generating capacity

~1 million DNA bases assembled every week

Up to 100,000 strains screened in parallel with the ultra-high-throughput EncapS technology

Expansive high-throughput screening capacity for cell-based assays

The Owl Platform

Sequence- and structure-based AI models

Assay-labeled AI models with data generated in-house

Structure-guided design with Rosetta and QM/MM

AI-guided engineering biologics for

- Binding affinity

- Expressibility

- Thermal or colloidal stability

- Reactivity and cross-reactivity

- Immunogenicity

- Multiplex binding

03 BIOLOGICS SCREENING

Developability assessment with functional and phenotypic screening

Extensive characterization of a biologic during the discovery process can help to derisk the later stages of clinical translation.

The Ginkgo foundry is an expansive facility dedicated to making biology easier to engineer. The foundry enables high-throughput screening with a range of biologics-relevant assays. We have the automation infrastructure, biological tools and human experts to quickly develop new assays for in vitro, cell-based or pooled in vivo testing.

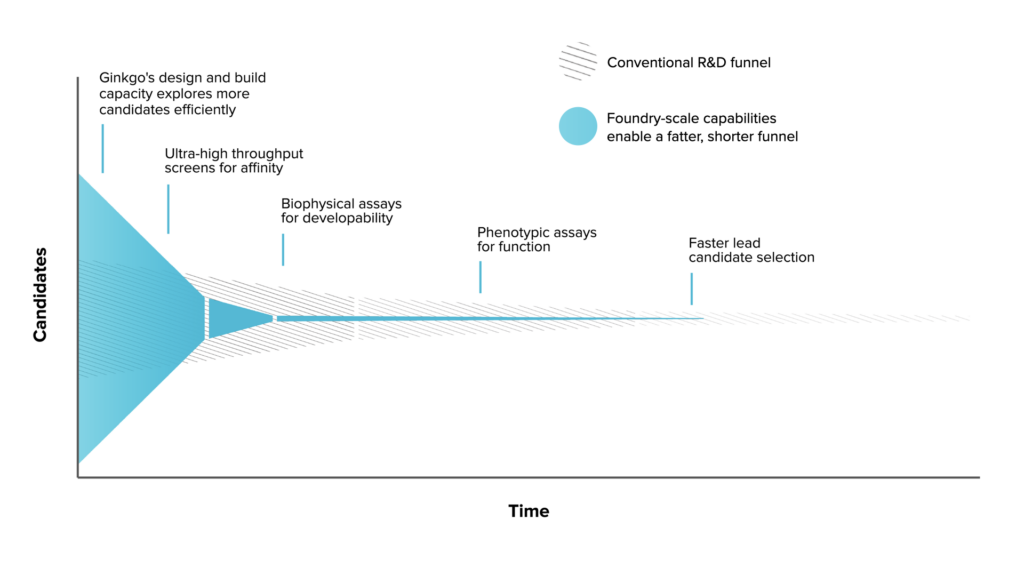

More data, faster developability decisions

The scale of the Ginkgo foundry allows us to build large libraries efficiently and screen them with multiple relevant assays in parallel. With a wider set of initial candidates and more data to select top-performers, we can accelerate the classic funnel process of therapeutic discovery.

Biophysical, biochemical and cell-based assays for

- Activity

- Binding specificity

- Binding selectivity

- Aggregation

- Fragmentation

- Charge heterogeneity

- Thermal stability

- Protein solubility

- Forced degradation

- Cell binding

- Epitope binding

- Titer

04 CELL LINES FOR MANUFACTURING

Select, characterize and improve cell lines for biologics production

Ginkgo offers a range of assets and capabilities to accelerate and help derisk the biologics manufacturing process. We work with common expression hosts including CHO and HEK293 cells. We have the expertise and the appropriate gene editing licenses to deploy CRISPR/Cas9 and recombinase-mediated engineering strategies.

By leveraging the power of the Ginkgo foundry, we can explore large combinatorial design spaces to identify expression constructs and cell lines with improved functional titers. We can optimize transformation protocols, production conditions, regulatory elements, integration sites, host genetic backgrounds and more.

Engineered cell lines can then be characterized at various production scales from Ambr®250 up to pilot-scale using an established network of CDMOs.

Host Selection

Evaluate genomic and functional titers and select top-performing lines via single-cell cloning

Identify knockout, knockdown, or overexpression targets using transcriptomics data from 1000s of gene candidates

Cell line characterization

Collect multi-omics data to identify actionable gene targets associated with performance limitations

Assess single-cell productivity with EncapS or conventional high-throughput workflows

Engineering & Improvement

Cassette optimization with host-specific synthetic promoters, integration sites or vector configurations

Targeted integration with CRISPR/Cas9 or Recombinase-Mediated Cassette Exchange (RCME)

Bioprocess Development

Design of Experiments (DoE) for process parameter optimization in Ambr®250 arrays

Consolidate winning strategies from an optimized host, transgene cassette and process conditions

05 YEAST FOR MANUFACTURING

Yeast expression systems for nanobodies and other protein biologics

For certain biologics, yeast-based expression systems can offer higher production efficiency as well as faster R&D cycles. Ginkgo has extensive experience in microbial protein expression systems, including for enzymes, nanobodies and other biologics-relevant formats.

Yeast offer several advantages as biologics production hosts. Downstream processing does not require viral filtration and inactivation. Because yeast are hardier than mammalian cells, they undergo less lysis during harvest and generate fewer HCP (Host Cell Protein) impurities. We estimate that microbial expression can yield up to 65% more product relative to mammalian cell lines of the same titer.

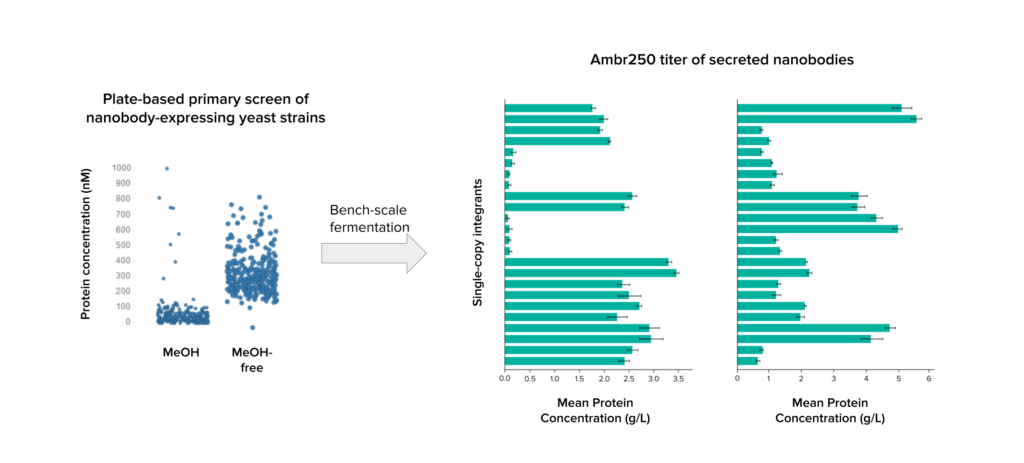

Rapid optimization of nanobody production in Pichia yeast

We screened a 2,000-member variant library for the expression of 2 different nanobodies. We identified strains with 3-6 g/L production titers in a single round of screening.

What makes Ginkgo’s Pichia special?

- Leverages a proprietary synthetic expression system

- Tested on 10,000+ proteins

- Methanol-free expression that outperforms best-in-class methanol systems by 20x

- Can achieve up to 25 g/L recombinant protein production

- Validated performance scalable from Ambr®250 to 10,000+ liters

HOW WE PARTNER

An innovation partner with tech you can’t get anywhere else

Ginkgo Bioworks is a pure platform company. We’re dedicated to helping our partners to advance their protein biologics rather than seeking to develop our own products in house. We offer a variety of partnership models to meet your technical needs, whatever your stage of the R&D process.

Our partners gain access to our industry-leading foundry automation infrastructure, our large libraries of partially and extensively characterized genetic assets and our world-class team of experts in cell engineering.

Why work with Ginkgo to develop your next protein biologic?

- Take control of your R&D spending by replacing fixed costs with variable costs.

- Avoid costs and delays associated with building your own infrastructure.

- Launch faster by starting from pre-characterized genetic elements.

- Gain access to our unique biological assets and industry-leading capabilities.

- Improve production titers and develop new manufacturing IP for your biologic in a variety of hosts

- Work with our team of dedicated experts across all stages of discovery.

Ginkgo is ready to partner with you to enable the next generation of protein biologics!

"*" indicates required fields