Overview

Empowering your enzyme R&D

Enzymes power biology, driving almost all of the chemistry that makes life possible. They can enable the manufacturing of complex APIs (Active Pharmaceutical Ingredients). Or enzymes may themselves be therapeutic agents, actively participating in a metabolic or cellular process. Ginkgo can support your enzyme R&D projects across all the ways in which enzymes are designed, built, tested, delivered to your patients.

Working with Ginkgo means running your project on the Ginkgo foundry, an expansive facility at the cutting edge of synthetic biology. The foundry brings together the latest in AI and computational design tools with high-throughput automation, allowing us to efficiently explore enzyme space to find the perfect design for your application.

Ginkgo offers end-to-end support for your enzyme engineering projects. Partner with us all the way from early stage discovery to developing a production and purification process for tech transfer to your cGMP manufacturer.

Enzyme R&D for a range of applications

- Pharmaceutical manufacturing

- Molecular diagnostics

- Novel or enhanced gene editors

- Therapeutic enzymes

- Enzyme payloads for cell or gene therapy

Solutions for

- Improved catalytic efficiency

- Reduced by-product formation

- Enhanced stability

- Increased production titers

- Lower manufacturing costs

01 GINKGO ENZYME INTELLIGENCE

AI-guided enzyme engineering supported by large biological datasets

AI unlocks new design spaces for enzyme engineers and new opportunities for enzyme-powered applications. Enzyme R&D projects at Ginkgo deploy AI tools at all stages: discovery of novel enzymes, structure-guided engineering, manufacturing and process optimization.

At Ginkgo, “Data is Queen”. Machine learning algorithms learn from data and are only as effective as the data resources that are used to train them. As software tools for performing AI-guided design become commonplace, Ginkgo’s partners benefit from the unique advantages of our proprietary in-house datasets and the data-generating capabilities of our foundry.

Ginkgo’s software platform for AI-guided design is Owl, so-named because it can see in the dark. Owl integrates with a full range of computational tools, selected by our enzyme engineering team and proven out over dozens of projects. Our human experts are equipped to choose the right approach for your application.

Enzyme Discovery

Computational Design

Enzyme Intelligence with Owl

Automated AI Platform

Generative AI

Model Fine-tuning

02 DISCOVERY & OPTIMIZATION

Identify a novel enzyme or enhance the performance of a known enzyme

Enzyme discovery projects begin with your desired reaction chemistry. Using AI-guided search tools and our large in-house DNA sequence databases, Ginkgo can identify unique candidate enzymes from diverse natural sources. The enzymes we discover often have novel sequences unlike those of previously described candidates, opening up new IP options for our partners.

Enzyme optimization projects at Ginkgo benefit from Owl, our AI-guided design software. Our foundry facilities for DNA assembly, assay development and high throughput screening allow us to quickly identify high-performance enzymes.

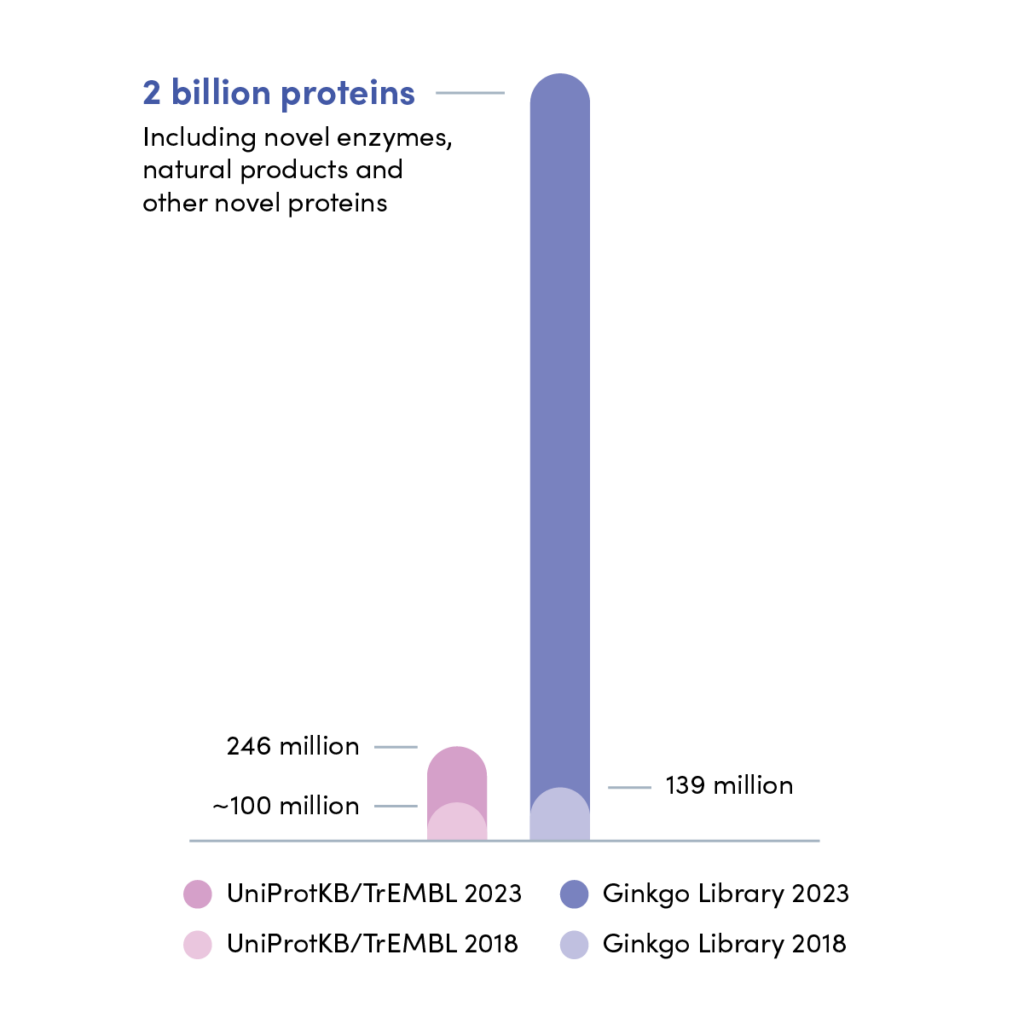

Metagenomic discovery projects search both public DNA data and our large in-house sequence libraries for unique enzymes with a desired activity.

With AI-guided search tools, we can discover enzymes with novel sequences or even previously undescribed reaction chemistries.

Optimize enzymes for

- Catalytic activity

- Enzyme stability

- Substrate specificity

- Expression level

03 EXPRESSION, FERMENTATION, & SCALE-UP

Manufacture your enzymes in our high performance, commercial-ready hosts

Cost-effective enzyme manufacturing requires a host strain that’s ready to scale. Ginkgo offers a variety of proprietary bacterial and fungal hosts along with the experience to help you choose the right strain for the right project.

Enzyme optimization is an integrated problem: the enzyme sequence, expression construct, host strain and fermentation conditions work together to determine the final production titer. At Ginkgo, we have the capability to optimize enzyme expression directly in the final production host, helping to reduce the risks associated with scaling up.

When your enzyme product is ready to produce at scale, Ginkgo can develop a fermentation process suitable for your manufacturing facility or for tech-transfer to your preferred CMO. We offer Design of Experiments (DoE) process optimization, followed by pilot fermentation bioreactors at a variety of sizes.

Ginkgo’s end-to-end support for enzyme manufacturers spans all the way to downstream processing and purification. Use our thermal, physical, and chemical capabilities to purify product samples at the proof-of-concept stage. Work with us to develop your complete, commercial process. Our team offers cost modeling and feasibility assessments at every stage to inform your decision making.

Bacterial and fungal host strains

- E. coli

- Bacillus

- Methanol-free Pichia pastoris

- Low viscosity Aspergillus niger

Fermentation capacity available for process optimization

- ~300 Sartorius Ambr® 250 bioreactors

- Reaction vessels at 1, 5, 10, 30, and 3,000 L

- 50,000 L vessels (with our manufacturing partners)

04 SUCCESS-BASED PRICING

For qualifying enzyme engineering projects, pay based on success

Ginkgo has over 15 years of experience in enzyme R&D. The depth of our experience gives us the confidence to offer success-based pricing for select projects. Contact us to learn more!

HOW WE PARTNER

An innovation partner with tech you can’t get anywhere else

Ginkgo Bioworks is a pure platform company. Rather than seeking to develop our own enzyme products in-house, we’re dedicated to helping our partners advance their enzymes to commercial deployment.

We offer a variety of partnership models to meet your technical needs, whatever your stage of the R&D process. Our partnership philosophy to align our commercial objectives: we succeed when you succeed.

A selection of our partners

Why work with Ginkgo to develop your enzyme?

- Take control of your R&D spending by replacing fixed costs with variable costs.

- Avoid delays and expenses associated with building your own infrastructure.

- Launch faster by starting from proven datasets and established workflows.

- Gain access to our unique biological assets and industry-leading capabilities.

- Work with our team of dedicated experts across all stages of enzyme R&D.

Ginkgo is ready to partner with you to enable the next generation of enzymes!

"*" indicates required fields