Our partner encountered a bottleneck in accessing and producing a key enzyme required for scaling-up their vaccines.

By leveraging Ginkgo’s cell engineering platform, our partner was able to develop an E. coli expression system for their enzyme expression. Combined with fermentation and processing protocol, we achieved a ten-fold increase in efficiency within a year.

Strain Engineering for Bio-Based Industries

Enzymes play a crucial role where traditional chemical methods are inadequate. Perfected through millions of years of evolution, these biological catalysts guide cellular processes with unparalleled precision. The capacity to extract these proteins from their natural environment and employ them to catalyze specific reactions has sparked a revolution across various industries, spanning from basic chemicals to pharmaceutical drug manufacturing. Industry stakeholders have recognized that substituting traditional exotic chemical catalysts with enzyme-based solutions often provides more adaptable, powerful, and cost-efficient alternatives for product development, while also potentially diminishing their ecological footprint. To preserve their competitive advantage, companies persistently seek innovative approaches to enhance enzyme production processes.

Ginkgo Bioworks’ Cell Engineering platform streamlines biological engineering via state-of-the-art, well-developed workflows. While traditional strain engineering can be a protracted and high-risk endeavor, our approach involves organizing our extensive experience and knowledge base into these workflows, resulting in a more efficient path for developing industrially-relevant strains and processes. This structured approach not only reduces the time spent searching for solutions but also empowers our partners with best in-class strain engineering for accelerating their product development, and ultimately, scaling to commercial manufacture.

The Challenge: Overcoming Enzyme Supply Constraints for Vaccine Production

Our partner, advancing vaccine production to meet global demands, faced supply chain limitations with a critical enzyme needed for their manufacturing process. Despite exploring commercial sources, they encountered a shortage. In-house production attempts fell short of scale-up requirements, highlighting a pressing need for a commercially viable production method for this essential enzyme.

Our Work: From Sequence to Manufacturing in less than One Year

We approached our partner’s protein expression problem by initiating two concurrent workflows: first, a Strain Engineering workflow was deployed, aimed at identifying elements that optimized the expression of their enzyme in E. coli.

Design: We developed a very targeted library of roughly 300 DNA expression constructs that we predicted would have a high probability of improving enzyme expression. The library tested different DNA recodings of the protein (while maintaining amino acid sequence), promoters, plasmid backbones, ribozyme variants, and ribosome binding sites (RBSs).

Build: Within weeks of designing these constructs, our in-house DNA synthesis team delivered these plasmids, which were transformed into the E. coli expression host.

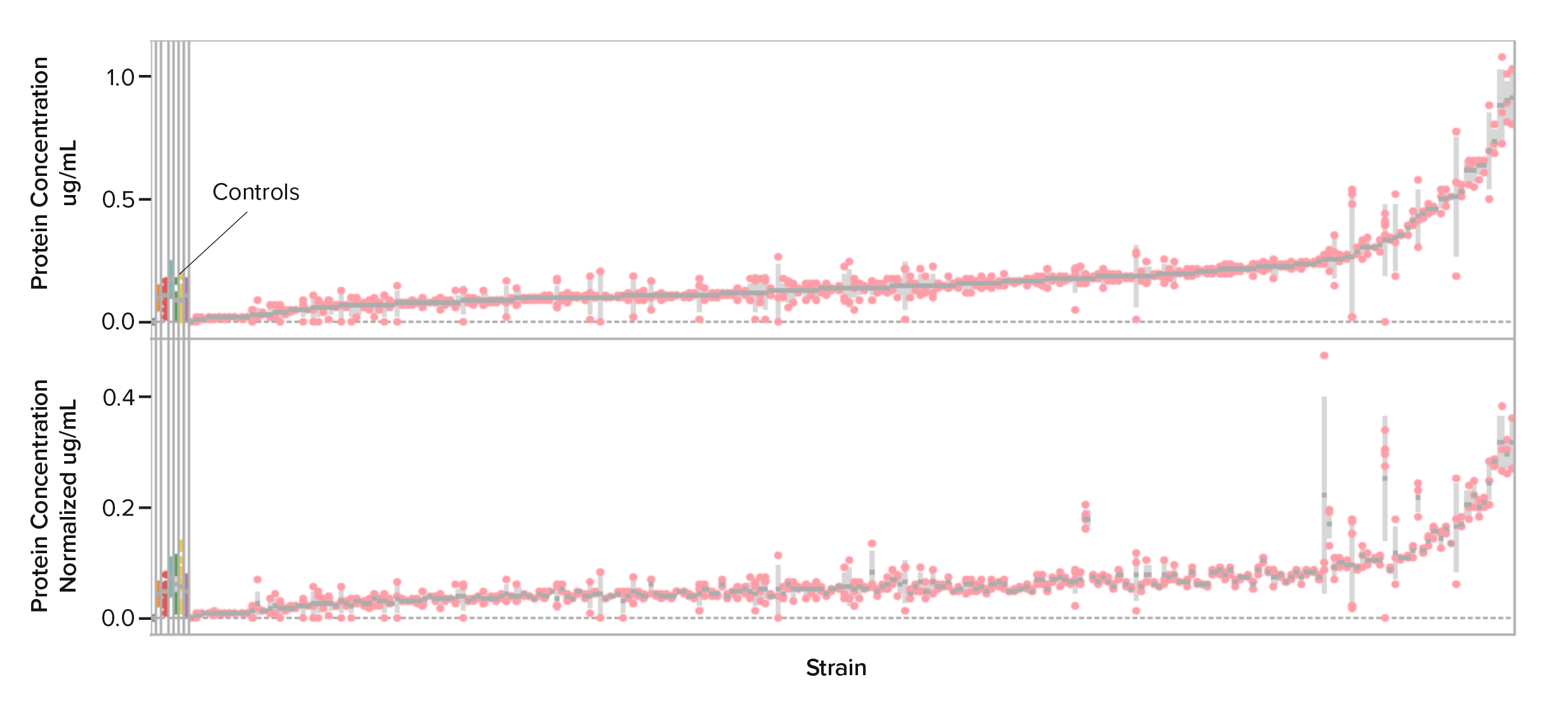

Test: By the time these strains were constructed, we had developed a targeted set of enzyme titer and activity assays. We screened the ~300 member library for enzyme expression of each of these library members, selecting the top-producing strains according to our assay.

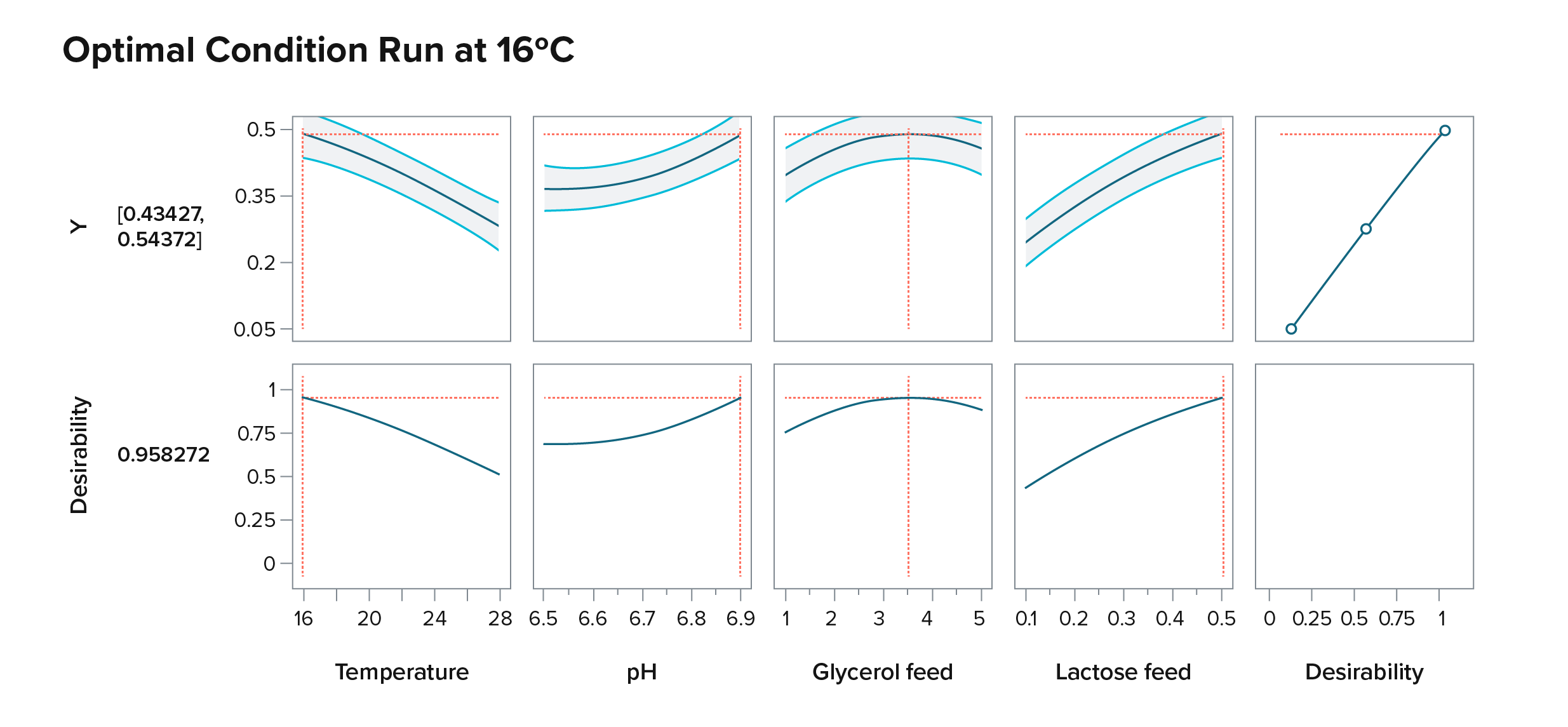

Simultaneously, we launched the Fermentation Process Development workflow alongside strain engineering. Initially, we pinpointed critical fermentation parameters, and used statistical techniques (Design of Experiment–DoE) to optimize the process based on identified parameters. By the time we established an effective protocol, strain engineering had identified promising candidates suited for this optimized fermentation.

Our Process Development team selected the best-performing strain and began industrializing the fermentation process to guarantee scalability. This phase focused on adapting our development to meet large-scale production needs, addressing potential scale-up challenges in advance.

This involved tailoring the fermentation media to support regulatory requirements for vaccine manufacturing. In doing so, this workstream also monitored the robustness of the fermentation feed profile making sure that the strain we were using was genetically stable throughout the entire fermentation run.

This dual workflow strategy ensured continuous knowledge exchange between the two streams of development, allowing us to effectively inform and enhance each phase. This synergy enabled us to deliver a scalable solution to our partner within their timeline.

The Outcome: Empowering a vaccine-manufacturing breakthrough

- Rapid Results: In under a year, our partner saw a 10-fold increase in protein yield from their starting point due to an optimized strain and fermentation process.

- Strain Engineering Success: Within the first six months, a single Design-Build-Test cycle reduced 300 potential strains to 22, achieving a 5-fold yield improvement.

- Fermentation Optimization: From the 22 strains, a single top performer was selected through Fermentation Process Development, performing well in scaled fermentation.

- Overall Improvement: The combined optimization efforts led to a 10-fold improvement over the initial strain, with industrialization ensuring scalability.

- Knowledge Transfer: The final two months focused on transferring our findings, enabling our partner to significantly surpass their previous year’s enzyme production in a single run.

- Market Entry: Leveraging exclusive rights to the newly developed process, our partner scaled up production to enter the global vaccine market.

Our Capabilities:

- Rational Strain Engineering: Ginkgo’s library of DNA parts and experience with a wide variety of host organisms means shorter development time and higher probability of success. Paired with analytics, Ginkgo’s Cell Engineering Platform, efficiently executes Design-Build-Test workflows to identify top-performing strains.

- Streamlined R&D: Pairing strain development with process development identifies strains that not only function well in the laboratory but translates that activity into the fermentation tank and industrial setting.

- Industrial Optimization: Development workflows take into account the constraints of manufacturing products at scale from developing industry-relevant protocols to monitoring genetic stability at scale.

- Tech Transfer: Successful projects require smooth integration into our partners’ pipelines. Our engineers are experienced in developing knowledge transfers and troubleshooting, empowering our partners with the technology we develop.

Work With Us

Ginkgo Bioworks’ Cell Engineering Platform brings actionable bio-based solutions.